Why is hemp the most ecological natural material in the textile industry?

Hemp is a forgotten material, decried, discredited and subject to stereotypes. Yet it is the most ecological natural material on the textile market! At a time when the whole world is worried about the planet, hemp and its ecological and technical advantages must make a comeback.

Moreover, it is a resistant and very pleasant material, ideal for shoes. That's why we chose to use it for the manufacture of KANA. We also want to encourage the return of this so virtuous textile sector in France and Europe.

We explain here why hemp is the most ecological natural material of the textile world through its history, its advantages and its relocation in the textile industry.

The first plant in textile history

Hemp is the first plant that mankind cultivated to make textiles. Already in the Neolithic period, it was cultivated in Asia, and from 600 BC, it was used to make royal clothes in China. After Asia, hemp is exported over the centuries, Europe and the rest of the world began to cultivate it.

- In France, as early as the Middle Ages, Charlemagne encouraged the cultivation of hemp.

- During the great maritime explorations of the 17th and 18th centuries, hemp experienced its golden age: being very resistant, it was used to make ropes and sails for ships that resisted wind and salty water.

- It was used until the Second World War, notably for stationery, military clothing and 80% of civilian clothing.

Unfortunately, hemp is often confused with its psychotropic cousin (cannabis), and this resemblance is still greatly lacking today.

Both were banned in 1937 in the United States with the Marijuana Tax Act, the decline of this fiber began throughout the world. In addition, with industrialization, synthetic materials derived from petroleum are imposed as new textile standards, not to mention the industrialization of cotton production which is now one of the main components of our clothing.

Thus, France, which is still one of the first hemp producers today, went from 176 000 acres cultivated in 1840 to 3 400 acres in 1939.

The hemp textile industry in Europe

Nowadays, France is the first producer of hemp in Europe, it is one of the only countries that have not totally stopped its cultivation following the American legislations.

French hemp has many uses:

- Insulation

- Component of car bodies

- Litter

- Cosmetics

- Food

- Medical

Unfortunately, the know-how in textile has completely disappeared in France. Just like the flax industry, of which we were the first producer in the world. There are only two French spinning mills left, such as Safilin, but their factories have been located in Poland for several years due to labor costs. It must be emphasized that our industrial tool has almost totally disappeared in the linen and hemp textile sectors.

Moreover, it is China that buys more than 80% of the scutched linen that it spins and re-exports to the old continent.

However, some people are fighting for the revival of the French hemp textile industry, such as the cooperative company Virgocoop, of which we are partners.

"Virgocoop is a cooperative organization whose aim is to accelerate the emergence of ecologically and socially responsible projects in our territories. Its first objective is to promote and encourage the development of hemp industry."

That's why we chose to get involved with Virgocoop. KANA is of course an opportunity to encourage the relocation of the hemp textile industry in France and in Europe. In France, this project is still at the test stage but it could soon be integrated into our production.

In the meantime, KANA's hemp is harvested in Spain and spun in Romania, where the know-how resists despite the reign of polyester and cotton produced mainly in Asia. It already allows us to relocate the textile industry in Europe and this is already a great victory!

Sustainable farming without damaging the environment

Hemp has many environmental benefits and it starts at the stage where it grows. Here is a small summary of its ultra beneficial growing.

- It can be planted anywhere: adapted to a majority of climates, it can be found from the arid mountains of North Africa to Siberia through China and Europe.

- Its smell repels pests, so no insecticide is used. It is even a sanctuary for some rare species like beetles and spiders.

- Hemp has rotating roots that go up to three meters below the surface. This root system has many advantages, first of all, at such a depth, the roots find water by themselves and therefore the plant does not need to be irrigated.

- This root system is so dense that weeds cannot grow: therefore no herbicides or fungicides.

- These famous roots also break the cycle of diseases in the soil, aerate the ground and feed it with the nitrogen that the plant produces, ensuring better yields for future crops. That's why it's called an excellent "head of rotation".

- Hemp stores a lot of CO2, imagine that one acre of cultivation stores as much CO2 as one acre of forest, that is 15 tons per year! This incredible plant therefore compensates for the CO2 that is produced during all stages of its life, from its growth to its transformation. It is also a very profitable plant since it produces, in only one acre, the same quantity of fibers of four acres of forest.

A plant that requires little water, that grows everywhere without chemicals and that purifies the soil while having a great yield, that is what we can call a responsible plant!

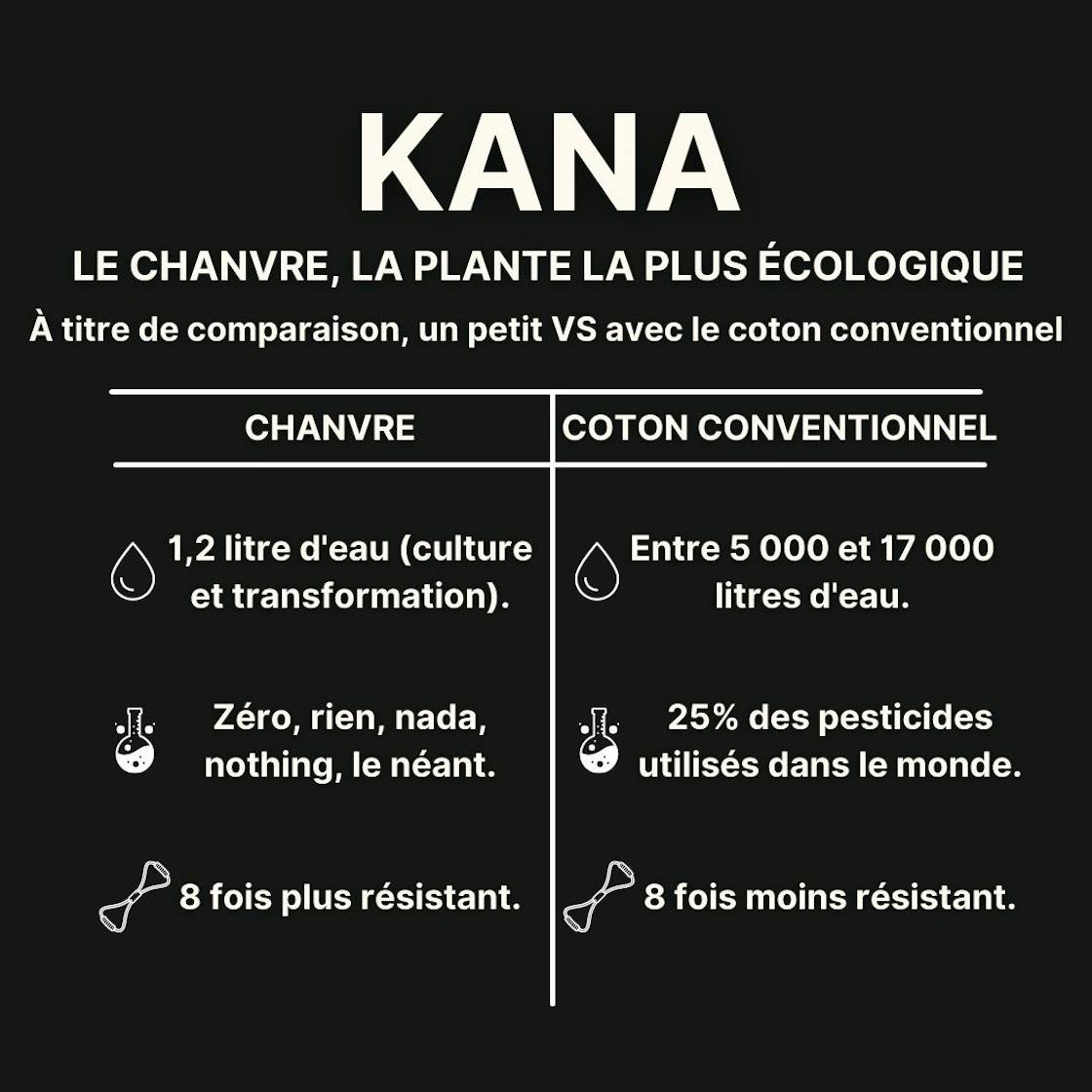

In comparison, cotton uses a lot of pesticides: a quarter of the world's phytosanitary products are used to produce this textile, which represents only 2 to 6% of the cultivated surfaces, whereas hemp does not consume any. Another point of comparison: water. The figures differ according to the variety of cotton, but it takes an average of 2000 liters of water to produce one kilo of cotton, against 300 to 500 liters for one kilo of hemp. Hemp is therefore much less greedy in all regards. It is then interesting to use this alternative, especially when we know that the cultivation of cotton in Uzbekistan has dried up almost the entire Aral Sea.

Mechanical and chemical-free processing

To produce a hemp fabric, several steps are required which are done by hand or mechanically.

These processes are more laborious than those used to produce cotton, which may also explain the decline of hemp. In order to understand the whole process, let's describe the plant a little: hemp is between 3 and 4 meters high. The fibers used to make textiles are located between the bark and the stem of the plant.

- Retting: once the stems have been cut, they must macerate for several days on the ground (or in water) so that the fiber is easier to extract.

- Grinding: the lengths of the plant are peeled to collect the fibers and the stem by removing the bark (as on the engraving below).

- Scutching: this consists in pulling on the hemp strand to separate the stem and the fibers.

- Combing: the fibers are combed to homogenize them into a "hemp tail".

- Spinning: finally, we can spin the fibers to make a thread!

With all these steps to get a raw yarn, no wonder cotton is more used. But hemp is much more ecological: in all this transformation, no chemical product is used since all the treatment is mechanical, and no water is used either (except for the retting if one chooses to soak the stems).

The technical advantages of resistance

To wear hemp is to honor a highly sustainable plant and an ancestral know-how. In addition, hemp also produces a high-quality fabric, for several reasons.

- Hemp fiber is very dense, and when woven, it is even denser. It is therefore not surprising that this fiber protects extremely well from ultraviolet rays by blocking solar radiation.

- Like wool, hemp is thermoregulating. Owning hemp textiles means being able to wear them both in summer and winter. Another common point with wool is that hemp is very resistant to mold and other fungi, these antibacterial characteristics are very interesting, especially to make sneakers that eliminate unpleasant smells!

- If it has been used for thousands of years, and even in the navy or the army, it is because it is a very resistant textile, especially to salted water and abrasion. It is six to eight times stronger than cotton. This strength is due to its extremely long fiber. So it's clearly extremely durable, and your hemp textiles will stay with you for a long time without stretching or getting damaged.

"You might think it's a rough material, but contrary to popular belief, hemp is quite soft and even gets softer as you wash it."

"KANA's fabric is almost as strong as good leather because hemp is the strongest natural fiber in the world. Blended with a bit of linen, it's also soft and breathable for ultimate comfort. We also added a waterproof treatment so this sneaker goes everywhere with you."

KANA takes advantage of the natural assets of hemp. It is extremely resistant, thermo-regulating and antibacterial. It is available in 6 colors with a version only in hemp and linen but also versions with recycled suede inserts and recycled rubber from the manufacturing scraps of soles.

The manufacturing is done by hand in a small workshop in the north of Porto as well as the sole in natural and recycled rubber. The assembling is a sewing-strobel which allows to have the maximum of flexibility and strength.

Producing a hemp sneaker is a way to revive an ancestral know-how, and to return to the common sense of responsible and European agriculture. It also allows you to wear resistant products, which will last a long time, with a simple and timeless design!

With all these advantages and technical characteristics, hemp appears to be a very nice material to work with. We are proud to be able to present KANA, which revives an ancestral know-how without destroying the planet!