Meeting with Jean-Michel, colorist at Filature Du Parc.

To continue our journey in the land of wool and recycling, we went to the Filature du Parc to meet Jean-Michel. His job is incredible and very rare in France.

The Filature Du Parc

The Filature du Parc is located in Brassac, in Tarn (we will tell you about its history in a future article). With 70 years of experience, it has been labeled a living heritage company since 2017. Since 2007, it is specialized in recycled yarn and has 48 employees, including Jean-Michel and Melanie, the two protagonists of our subject of the day.

In this workshop, sweaters are received and then frayed. This technique is called defibering and is the result of several years of development. It is what allows us to end up with a wool that looks like a virgin material, but this process is patented and well guarded, so we can't tell you more.

After the defibering stage comes Jean-Michel, the spinning mill's colorist. His job consists in mixing the different colors of wool to create new ones, and it is quite a know-how! We were able to meet him and his apprentice Melanie, so they could tell us more about their job.

Jean-Michel

To become a colorist, Jean-Michel did not follow any training, he learned on the job. To reach this position, which attracted him very much, he climbed the ladder within the spinning mill before becoming the apprentice of his predecessor. To become a good colorist, it takes 4 years of training. This complex skill requires rigor, a good knowledge of technical parameters, precision and a very good eye. He has been creating the colors of our future yarns for 13 years now.

A day as a colorist

A typical day as a colorist usually consists of creating a new yarn with products provided by customers. This means checking that the raw material is available. If it is, he can create the color, if not, he composes a color with similar materials.

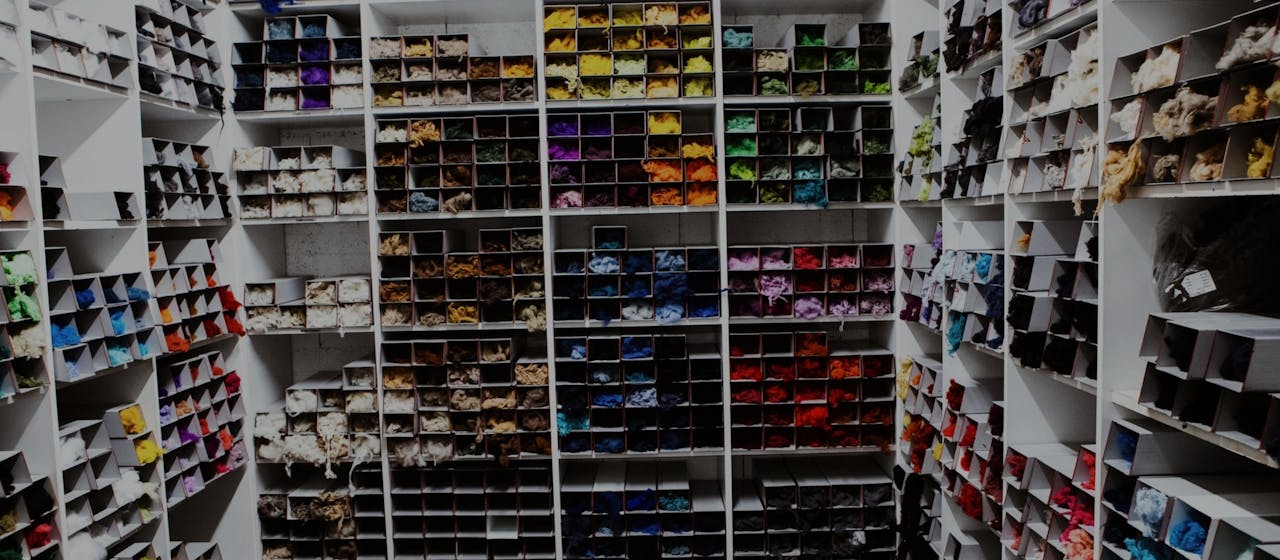

Jean-Michel's favorite thing is to create new colors! This happens about 10 times a year: his color range is already so vast that it is not necessary to create new shades every time. In his office, protected from the light, are stored about 500 recipes, the oldest of which date back to the 80s. These recipes really look like cooking: we couldn't take a picture of them, but it's the precise weight of each shade to be mixed.

To create a new color, Filature du Parc's customers send a reference, and Jean-Michel tries to find a way to get close to it: it is often difficult to achieve the same result as on paper. Some colors are more complex than others: browns or reds are often very nuanced (with yellow, purple, pink reflections...) and it can be easy to get lost. In this case, it is better not to get stubborn, nor to get angry, and to resume this work the next day. The time to create a color can vary, it is usually 1 or 2 days, but can go up to 3 days for more complicated colors.

Concerning the future of his profession, Jean-Michel is optimistic: he has been training Mélanie for a year and a half: "The next generation is here".

A complex but mastered technique

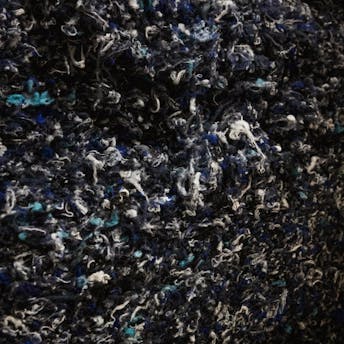

To create new colors, it is necessary to mix several batches of fiber. After having weighed and added a precise quantity of each shade, Melanie and Jean-Michel pass them in a mini carding machine (a machine used to stretch the fibers and to mix them together with pins). It takes about 3 runs for the sample to be homogeneous.

After mixing the sample, Melanie checks its color and compares it to the customer's reference in a lighted box. On the box, one can choose the light settings between daylight, department store, or UV light.

This process requires great precision and must be repeated until the closest color to the desired one is achieved. That's why training takes so long!