All about recycled wool

We use low-impact natural raw materials in priority. We already wrote about hemp, now let's move on to what has made up our flagship products since the beginning : recycled wool!

The great history of wool

To begin, a little history. Note that we will focus on sheep wool in this part. There are other animals that can produce wool, like the cashmere goat, the angora rabbit, the yak or the camelids, but to retrace the history of each of these fibers would require a lot of time and would make this article rather heavy. So, let's get back to our topic.

Wool began to be exploited around 10,000 BC in Minor Asia (also the starting point of hemp) for clothing and shelter. At that time in Europe, the sheep are more hairy than woolly and we do not weave their wool, even if we wear their skins. It is thought that it is from the fourth millennium BC that woolly sheep are introduced in the Mediterranean basin.

During the antiquity, the Romans are fond of wool, in particular of the one woven by the British who already possess a great know-how, following the example of the Egyptians (Yes, wool in a hot country! We keep telling you that it is a thermoregulating material).

In the Middle Ages, all of Europe weaves and uses wool, and great fortunes are built around this fiber, like that of the famous Medici who are part of Arte Della Lana, a corporation of Italian wool makers. Christopher Columbus and Hernan Cortez even took sheep to America, which allowed them to start using their wool as well. Spain then forbade the export of sheep and punished it with the death penalty in order to keep control of this trade and ensure a source of income.

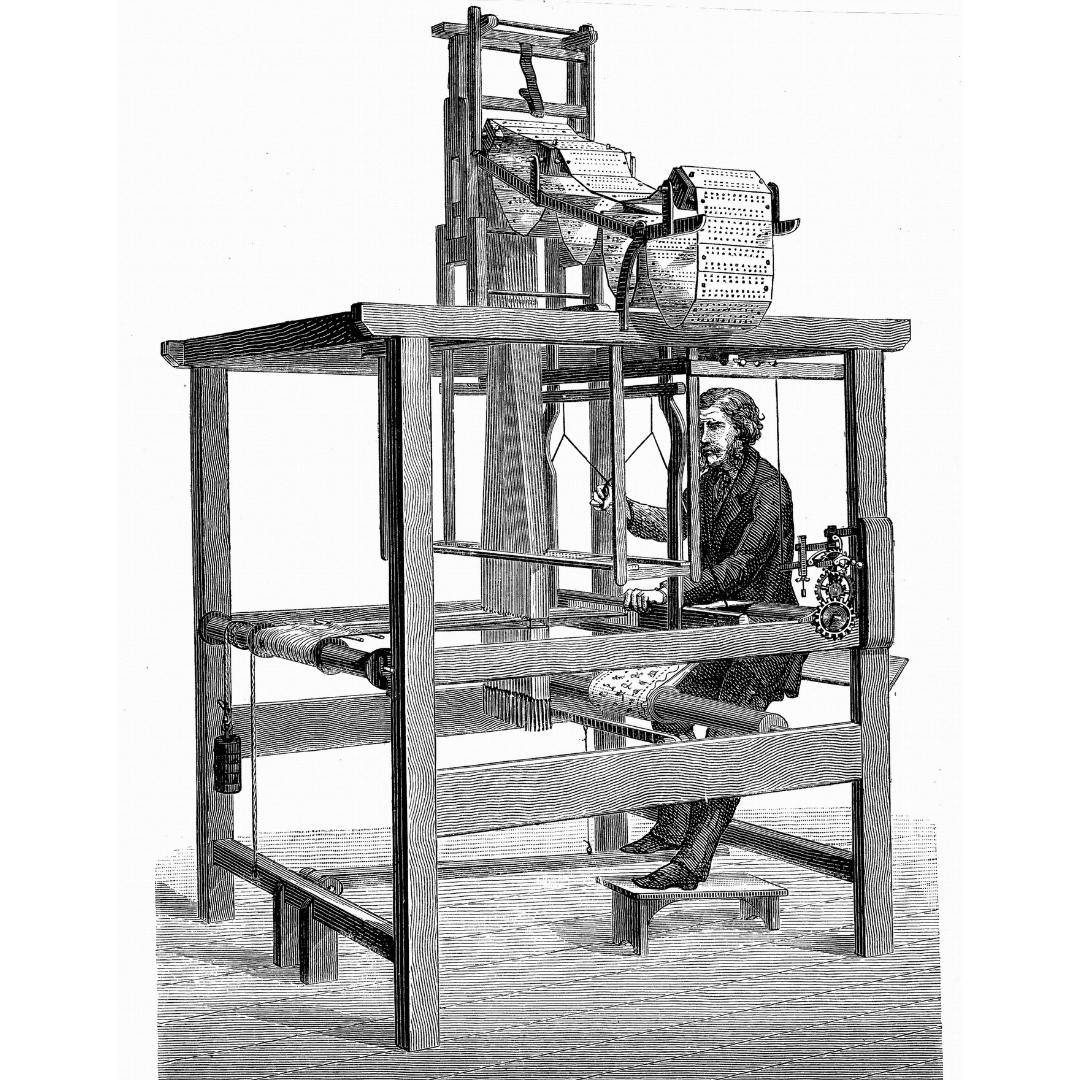

In 1801, in France, Jacquard weaving was invented, which allowed a yield twelve times greater than hand weaving. In spite of technical progress, the wool industry is in strong competition with cotton, just as hemp was. Today, in France, it is in strong competition with the wool of the New Zealand merino and its industry is little developed.

The problem with virgin wool

China and Australia are the two biggest producers of wool in the world. This wool has a big impact on the environment with several factors firstly linked to the breeding of sheep:

• The emission of greenhouse gases close to those of cattle

• The pollution of water and groundwater, because of excrements and chemicals (anti-parasite treatments...)

• - The destruction of vegetation and soil, with the consequence of soil erosion.

Not to mention the sometimes disastrous conditions of breeding and shearing for the animal's well-being and the stages of transformation of the wool into fiber which involve water, energy and chemical dyes.

Finally, this wool comes from the other side of the planet. The transport of a Chinese or New Zealand wool to Europe adds to an already very significant environmental impact.

For our sneakers, we prefer a recycled wool, spun and woven in Tarn (81), which comes from sweaters of French and European clothing depots. For our sweaters, we use merino wool recycled in Italy.

Indeed, the recycled wool remains more sustainable to this day since it is 98% less impactful for the environment than a new fiber according to a study conducted by the Filature Du Parc. By recovering a material already produced, there is no impact related to breeding and, as we will see, its transformation process is much cleaner.

How are new and recycled wool processed?

To transform new wool into a textile, there are different techniques and steps to follow. For example, before the invention of the comb and shears, which probably took place during the Iron Age, men plucked wool by hand. This step is now replaced by shearing the animals.

After removing the wool from its original owner, the types of wool can be sorted according to their quality and the presence or absence of impurities. These impurities must then be removed. To do this, the wool is soaked to remove the grease, then washed.

Once rinsed and dried, the wool goes to the carding stage. This operation is done with a frame equipped with spikes. The wool is passed over it to be able to untangle it and remove the last impurities. After a last step called unraveling to homogenize the fiber, it is ready to be spun.

We can also mention the step of the fulling, which consists in "whipping" (originally with the feet) the wool in a tank (with water and clay generally) to degrease it even more and to make it more valuable.

Transforming the wool into yarn is done by successive stretching on spinning machines. Then, it can be dyed, woven or knitted according to the quality and textile characteristics that we want to obtain.

Concerning the recycled wool, no resources are taken again in the nature because it comes from wool sweaters resulting from French and European clothing relay.

Its transformation steps save water, energy and chemical dyes compared to the steps of a new fiber detailed above.

In our spinning mill in Tarn (81), this is how we regenerate the wool that will be used to make our sneakers:

• Receipt of woolen sweaters coming from clothes relay stations. These are sorted by color, so there is no need to re-dye the wool!

• Defibration of these clothes which will be recycled by a unique and patented process. It is the result of 10 years of research in partnership with French and Italian engineers.

• Jean-Michel, the colorist and star of the spinning mill, will be able to mix several colors of these defibered sweaters (which now look like new wool) to obtain new ones.

• The regenerated fibers go through the classic spinning process (carding + spinning).

Then, this yarn is sent to Castres, still in Tarn (81), to Pierre who will weave it with love to obtain the final material that you find on our sneakers, a soft, flexible material but dense enough to be robust and waterproof. Moreover, recycled wool has the same properties as virgin wool, but it is much more eco-friendly.

What are the environmental benefits of recycled wool?

Recycled wool and new wool have the same characteristics. Both are thermoregulating and antibacterial. Wool, recycled or not, keeps us warm in winter and cool in summer. It also allows us, thanks to its anti-bacterial properties, to limit odors ( from feet, in the case of a shoe).

On the other hand, recycled wool is much more ecological and also resistant.

- No animal suffering and pollution linked to the breeding often far away (China or New Zealand). So we avoid other sheep to be sheared (and when we think of the mulesing on merino sheep, a practice which consists in tearing off their skin at the tail to limit the infections, we prefer to reuse what already exists).

- In general, recycled materials save all the resources needed to manufacture a new material, while avoiding the waste generated by the fabrics already produced.

- Regeneration of recycled wool is also particularly environment-friendly, with great savings in water and energy due to its mechanical process. Also the wool in our sneakers is not dyed a second time. In all, recycled wool is 98% less impactful than new wool.

Thermoregulator, insulator, anti-bacterial, natural, zero waste... Recycled wool has everything to please!

Natural materials have been used by mankind for thousands of years, and they convey an ancestral know-how that allows us to produce exceptional shoes. Using recycled wool was an obvious choice, since it can be found in France, participating in a short circuit and respectful of the planet. Long live recycling!

Sources :

Le Béret Français, Stefane Girard, Stefane Girard, Wikipédia, Wikipédia, Princesse Foulard.